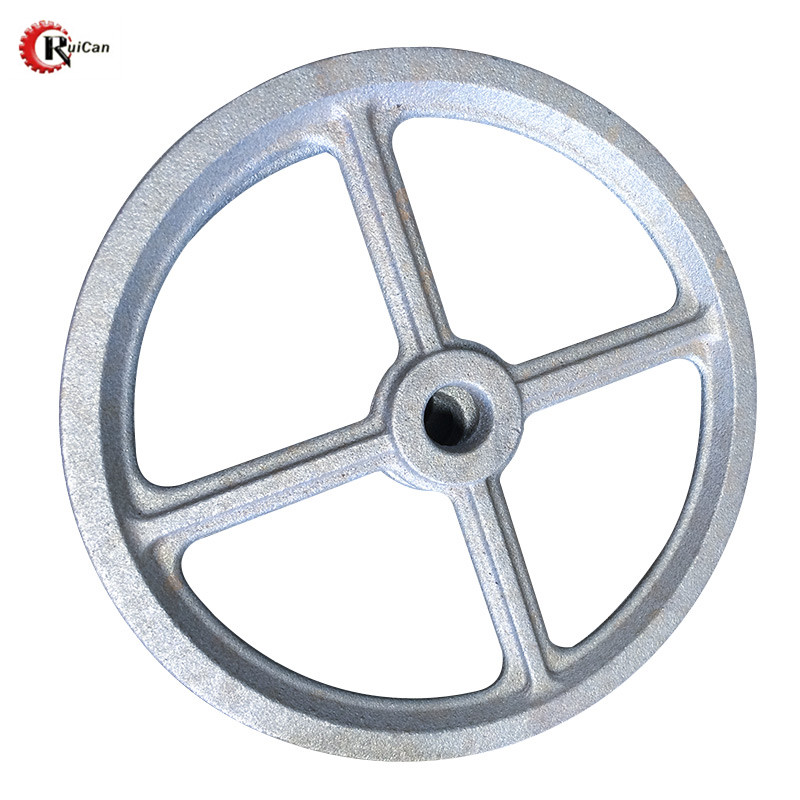

ASTM4140 na-agbaghara isi

Get Latest Price| Ụdị Ụgwọ: | L/C,T/T,D/P,Paypal |

| Enweghi ike: | FOB,CFR,CIF,EXW |

| Ụgbọ njem: | Ocean,Land,Air |

| Port: | NINGBO,SHANGHAI |

| Ụdị Ụgwọ: | L/C,T/T,D/P,Paypal |

| Enweghi ike: | FOB,CFR,CIF,EXW |

| Ụgbọ njem: | Ocean,Land,Air |

| Port: | NINGBO,SHANGHAI |

Eke: Ksst

| Agedị ngwugwu | : | Akpa akpa, katon, pallets, na ngwugwu ndị ọzọ dị ka ndị ahịa chọrọ |

The file is encrypted. Please fill in the following information to continue accessing it

ASTM4140 na-agbaghara isi

Akụkụ igwe ọrụ ugbo

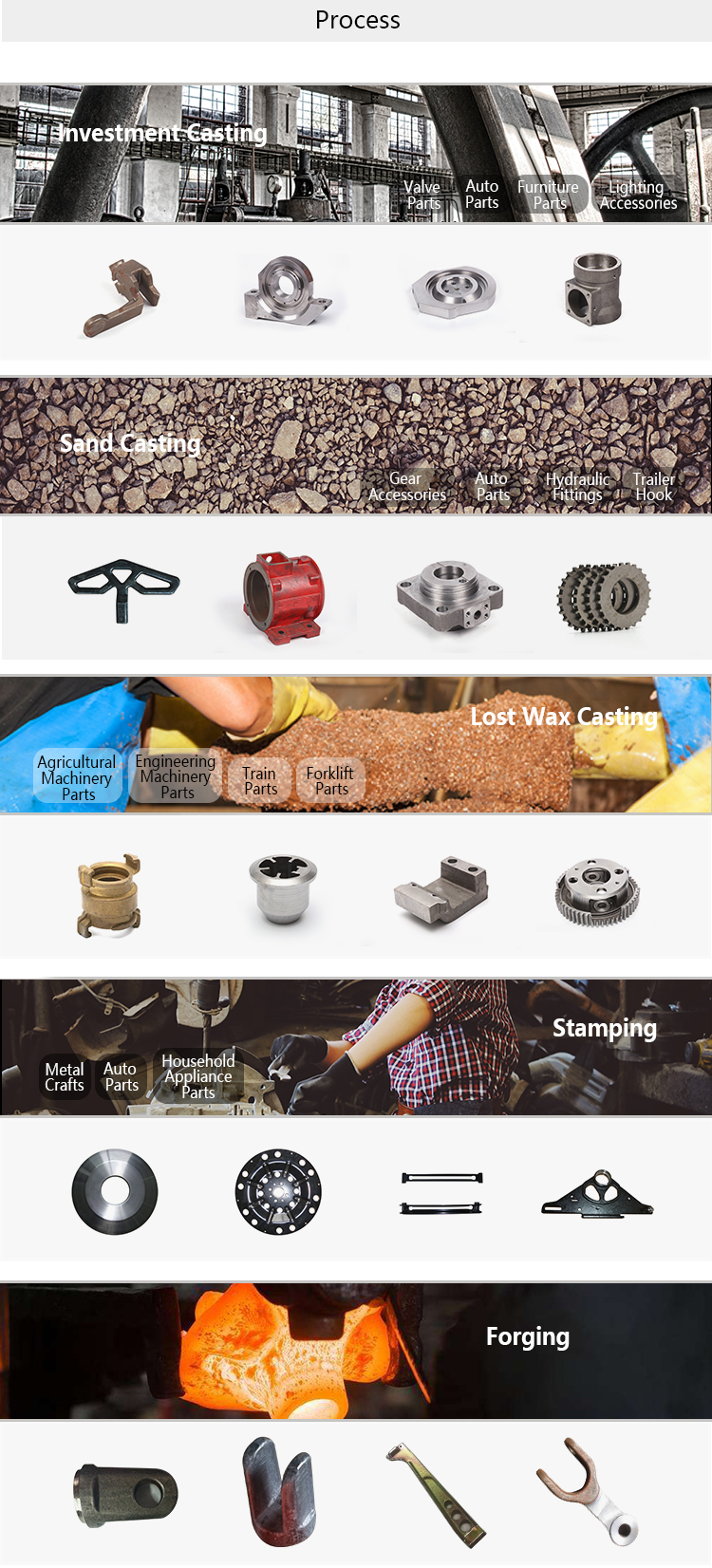

Anyị na-eme ihe na:

1. Akụrụngwa nke ájá (ígwè isi ígwì, ígwè na-akụ, aluminom, wdg)

2. Itinye ego (igwe mkpuchi carbon, igwe anaghị agba nchara, nchara nile, wdg.)

3. Dọkịta na-anwụ (aluminom, zinc, wdg)

4. Igwe eji eme (CNC LETE, LETE, LETE, igwe na-egwuri egwu, igwe na-eji igwe, wdg)

Akwụkwọ Asambodo: ISO9001: 2015, ts16949

|

Item Name

|

According To Drawings Hot or Cold Forging Metal Parts

|

||

|

General Products

|

Metal Parts Solution for Vehicle, Agriculturemachine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, fly wheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

|

||

|

Process

|

Forging , Press

|

||

|

Blanks Tolerance

|

+/-0.3~+/-2 mm

|

||

|

Applicable Material

|

Carbon steel, Low Carbon steel, middle carbon steel, 40Cr, 20CrMnTi, 20CrNiMo etc.

|

||

|

Forging Blank Size

|

142 mm- 300mm or according to customer requirement

|

||

|

Blanks Weight

|

Range from 0.1kg-1000kg

|

||

|

Applicable Machining Process

|

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc.

|

||

|

Machining Tolerance

|

From 0.005mm-0.01mm-0.1mm

|

||

|

Machined Surface Quality

|

Ra 0.8-Ra3.2 according to customer requirement

|

||

|

Applicable Heat Treatment

|

Normalization , quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching

|

||

|

Applicable Finish Surface Treatment

|

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting,

|

||

|

MOQ of mass production

|

100 pcs

|

||

|

Lead Time

|

25~45 days for steel forging metal parts

|

||

Nkwupụta nzuzo: Nzuzo gị dị anyị ezigbo mkpa. Companylọ ọrụ anyị na-ekwe nkwa igosipụta ozi nkeonwe gị na mgbasa ozi ọ bụla na-egosi na ọ bụla e ji ikike doo.

Dejupụta ozi ndị ọzọ ka ọ nwee ike ịkpọtụrụ gị ngwa ngwa

Nkwupụta nzuzo: Nzuzo gị dị anyị ezigbo mkpa. Companylọ ọrụ anyị na-ekwe nkwa igosipụta ozi nkeonwe gị na mgbasa ozi ọ bụla na-egosi na ọ bụla e ji ikike doo.